Sodium on the move

95 percent of solar panels installed in Germany are based on crystalline silicon. In recent years, more research has been conducted into alternatives that can be produced more sustainably, used more flexibly and recycled in a way that is better for the environment. One of those alternatives is known as a “thin-film solar cell”, in which several layers of different materials are combined. “The layers are vapour-deposited directly onto a substrate, which could reduce production costs compared to classic silicon cells,” says Professor Roland Scheer, who is leading the photovoltaics research group team at the MLU. “Thin-film modules are also very light and can be produced as flexible film, which significantly expands their range of applications.”

The research group led by Roland Scheer is researching modules in which the absorber layer (the area in which solar energy is converted into electricity) consists of copper, indium, gallium and selenium (CIGS). Solar panels are already being produced like that on an industrial scale. A process has become established in which the CIGS alloy is applied with the addition of sodium. The sodium acts as a catalyst for the controlled growth of the alloy and ensures a higher concentration of charge carriers. In comparison with similar thin-film modules, sodium doping can increase efficiency by up to 15 percent – a considerable gain in the struggle for optimised efficiency.

However, the photovoltaics team has discovered that this very catalyst can also cancel out some of the efficiency gained. Scheer, “Under environmental influences such as light and moisture, sodium ions migrate to the surface of the CIGS layer and impede electron transport. However, this only happens during production as long as the cells are not sealed.”

Combined processes in an ultra-high vacuum

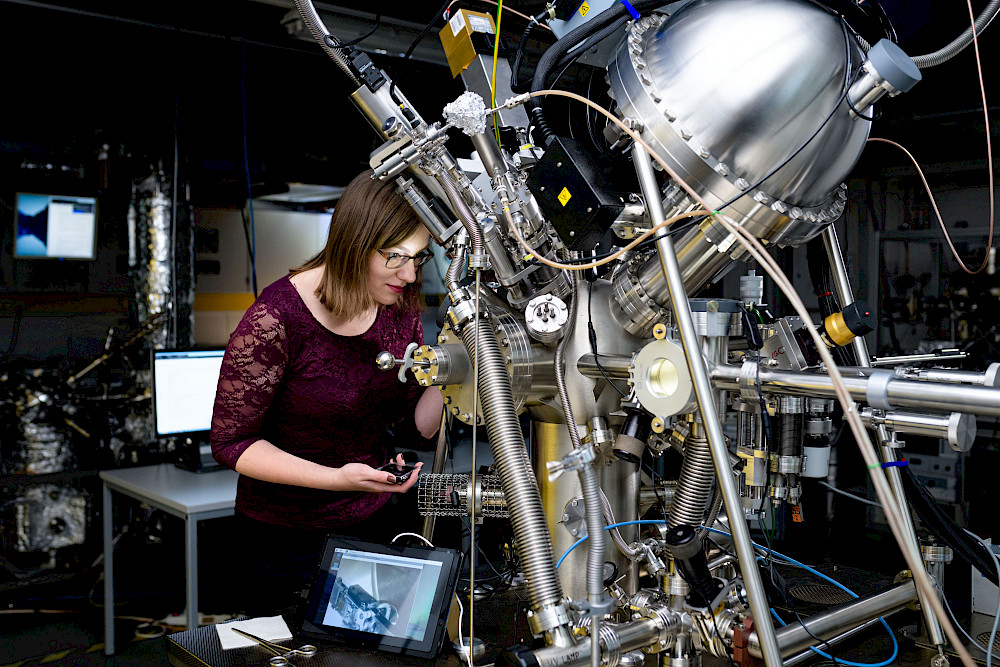

In order to investigate such defects and their causes in greater detail, Roland Scheer and Dr Stefan Förster from the Surface and Interface Physics group have launched a research project with funding from the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation). Their experiments are built around an ultra-high vacuum system – only interstellar space offers a cleaner vacuum. This is achieved using several high-performance pumps. In addition, the entire apparatus, which weighs around half a ton, is heated to 130 degrees Celsius over three days. “This is necessary to remove the last impurities inside,” explains Stefan Förster. “After all, we want to keep out external influences as far as possible.”

Stefan Förster and his doctoral candidate, Philine Stötzner, have developed a method for characterising the solar cell samples, which are approximately one square centimetre in size. Their method is unique around the world: In the first step, the distribution of the elements on the CIGS layer is determined using a photoelectron spectrometer. “This enables us to show how much sodium has migrated to the surface of our samples,” explains Philine Stötzner.

In the second step, the researchers examine the carrier lifetime, which is crucial for the electronic properties of the solar cell: A laser sends ultra-short pulses of light onto the surface of the sample, releasing electrons in a similar way to sunlight. When the excited electrons return to their original state, they emit light that is then detected by a highly sensitive sensor. Stötzner, “The faster the electrons return to their original state, the worse the photovoltaic efficiency of the material. We’ve proven beyond doubt that the sodium atoms on the surface of the solar modules dramatically increase this unwanted effect.”

In only the first year of her doctoral thesis, Philine Stötzner has already managed to integrate both measurement methods – electron spectroscopy and time-resolved photoluminescence – directly into the high vacuum system.

Light and oxygen result in surface defects

The team is conducting highly controlled experiments in which the samples are exposed to different influences to determine which specific factors promote surface defects. For example, the absorber surfaces are irradiated with white light and contaminated with oxygen over different periods – from one minute to three days. “We’ve found that it’s especially the combination of these influences – the concurrence of light and oxygen – that causes the sodium to reach the surface of the samples, resulting in the electronic defects,” says Stefan Förster.

The MLU team believes that the knowledge gained through their experiments will soon be incorporated into the industrial production of thin-film solar panels. And this does not necessarily mean that they will have to be manufactured in a vacuum; the layers are already being vapour-deposited under protective gases, which largely prevents contamination with oxygen. However, the additional exclusion of light in certain phases of production could further increase efficiency. The combined vacuum method developed over the course of the joint project is by no means limited to solar cells – it can be applied universally for research on and with semiconductor materials.

Professor Roland Scheer

Institute of Physics

Telephone +49 345 55-25490

Mail roland.scheer@physik.uni-halle.de

Dr Stefan Förster

Institute of Physics

Telephone +49 345 55-25363

Mail stefan.foerster@physik.unihalle.de

Philine Stötzner

Institute of Physics

Telephone +49 345 55-25364

Mail philine.stoetzner@physik.unihalle.de